运行稳定, 效果显著,口碑好!

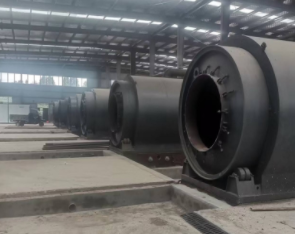

,注册资金 2000 万元)。位于河南省商丘市经济开发区。 位于商丘市经济开发区,注册资金 2000 万元。是一家从事环保设 备研发制造、销售及售后服务于一体的技术企业。全面通过了 ISO9001 质量管理体系、 ISO14001 环境管理体系、GB/T28001 职业健康安全管理体系和 CE 等国际认证。 亚科环保致力于有机固废处理一站式服务、有机固体废弃物热裂 解等综合类一站式服务项目的投资建设。